AJANCAD

AJANCAD

- Tasarım için gerekli çizim komutları ve hazır şekil kütüphanesi

- .Dxf dosyaları içe aktarma

- Geniş font/stil seçimleri ile şablon harf/rakam tasarımı

- Yoğun vektörel çizimleri en az noktadan geçen vektörlere indirgeme

- .Dxf üzerinde otomatik hata denetimi ile çizim hatalarını tespit etme ve düzeltme

- Otomatik markalama ve açık kontur kesme

AJANCAM V8 SÜRÜMÜ İÇİN PC DONANIM TAVSİYELERİ

Aşağıda AJANCAMV8 yazılımı için kurulacak ideal bir bilgisayarın özelliklerine değinilmiştir. Seçimize göre program hız performansında artış yakalanacaktır. Donanım seçimi yaparken size yardımcı olması dileğiyle…

AJANCAM V7 sürümü ile birlikte Vista ve XP işletim sistemi teknik desteğini bırakmıştır. Bu işletim sistemine sahip müşteriler AJANCAM V6 sürümünü kullanabilirler.

| Orta | Maximum | |||

| İşletim Sistemi (OS) | Windows 7 | 64Bit | 64 Bit | |

| Windows 8, 8.1 | ||||

| Windows 10 | ||||

| İşlemci (CPU) | Intel | Core i5 | Core i7 or Higher | |

| Generation | 7th | 8th | ||

| AMD | Ryzen 5 | Ryzen 7 | ||

| Architecture | Zen | Zen | ||

| Bellek (RAM) | DDR4 8GB | DDR4 16 GB or Higher | ||

| Gerekli Disk Alanı | 2 GB | 2 GB | ||

| Önerilen Ekran Çözünürlüğü | 1920x 1080 | 1920x 1080 | ||

| Erkan Kartı | DIRECTX | 12 | 12 | |

| NVIDIA | GeForce 900 Series | GeForce 10 Series | ||

| AMD | Raedon 300 Series | Raedon RX Vega Series | ||

| Ekran Kartı RAM | 2 GB | 4 GB | ||

KURULUM GEREKSİNİMLERİ

Yazılım Gereksinimleri

| Windows 7 SP1 |

Windows 8

|

Windows 8.1

|

Windows 10

|

| DirectX 11 | DirectX 11 | DirectX 11.1 | DirectX 12 |

| .Net Framework 4.5 | .Net Framework 4.5 | .Net Framework 4.5 | .Net Framework 4.5 |

Windows 7 Notlar

Service Pack 1 windows7 işletim sisteminde yüklü olmalıdır.

Bakınız: https://support.microsoft.com/en-us/help/15090/windows-7-install-service-pack-1-sp1

Windows 7 Platform Güncellemesi

|

Windows 7 için platform güncelleme yüklemesi gerekmektedir.

Kullanıcı aşağıdaki adresten indirebilir.

https://www.microsoft.com/en-us/download/details.aspx?id=36805

Ve detaylı talimatları buradan okuyabilirsiniz. Here

For 32 Bit, Windows6.1-KB2670838-x86.msu

For 64 Bit, Windows6.1-KB2670838-x64.msu

Opsiyonel: Grafik kartı ile ilgili sorunlarla karşılaşıyorsanız lütfen aşağıdaki aşamaları takip ediniz.

Grafik kartı sürücüsünü güncelleme (Opsiyonel)

Kullanıcılar grafik kartı sorunları yaşadıklarında aşağıdaki gibi grafik kartı sürücülerini güncellemeyi denemelidirler.

- Windows tuşuna basılı tutarak ÇALIŞTIR iletişim kutusunu açın,ardından R tuşuna basın,msc yazın ve TAMAM düğmesine basın.

- Device Manager,kısmını göreceksiniz Display adapters, üzerine tıklayınız. Mouse sağ tuş Update Driver Software seçiniz.

- Eğer güncelleme bulursa bilgisayarınızı yeniden başlatınız. Eğer windows sürücü bulamazsa aygıt yönetici web sitesinden aramayı deneyebilir ve kendi yönergelerini uygulayabilirsiniz.

WINDOWS UPDATE (Opsiyonel)

- Başlat düğmesine basın. Arama paneline “Windows Update” yazın.

- Seçin “Güncellemeleri kontrol et”.

- Güncellemeleri seçin ve yükleyin.

ABOUT US

ABOUT US CUSTOMER SERVICE

CUSTOMER SERVICE TECHNICAL SERVICE

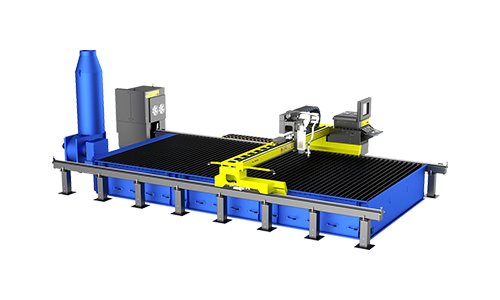

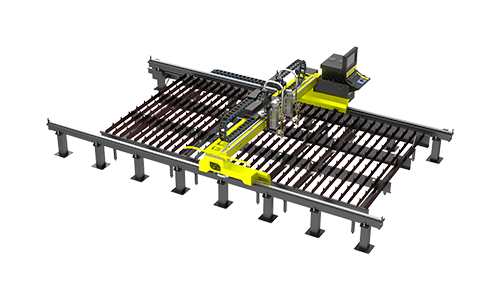

TECHNICAL SERVICE Standard CNC Plasma

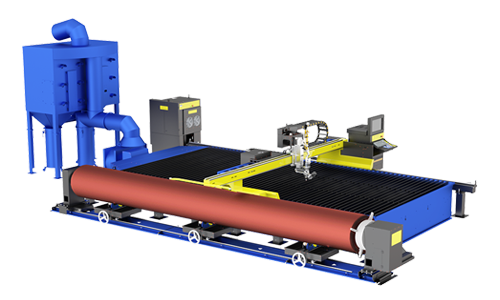

Standard CNC Plasma  Combined CNC Plasma

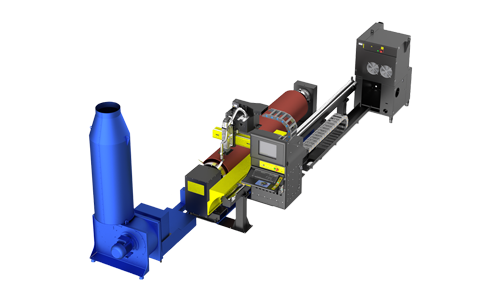

Combined CNC Plasma Pipe CNC Plasma

Pipe CNC Plasma  Oxy-Fuel CNC

Oxy-Fuel CNC MACHINE SOFTWARES

MACHINE SOFTWARES EDUCATION

EDUCATION DOCUMENTS

DOCUMENTS